Get certified in perfroming DIC experiements, enhance your professional credibility, prove your knowledge and skills, and enrich your reputation as a DIC practitioner

Learn the DIC fundamentals, specialize in new applications, or find out how DIC can revolutionize your product development

Join the largest and fastest growing network of engineers, technicians, experimentalists, researchers, academics, and product developers using DIC

Join a committee and help the society continue to grow and expand

Find software, discover new DIC-related research, or network with other DIC enthusiasts

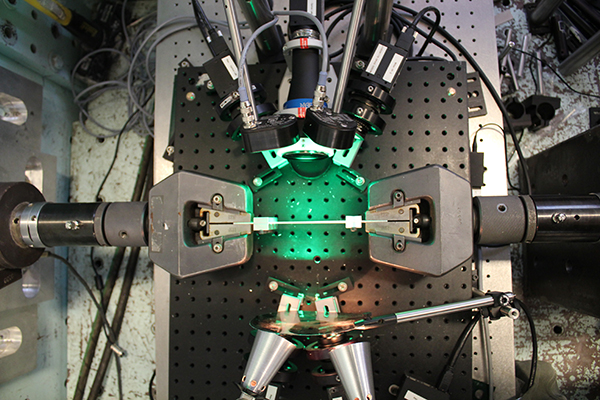

Learn the fundamentals of setting up DIC experiments

Verify your DIC code, explore algorithmic nuances, and network with other code developers

Discuss recent DIC publications

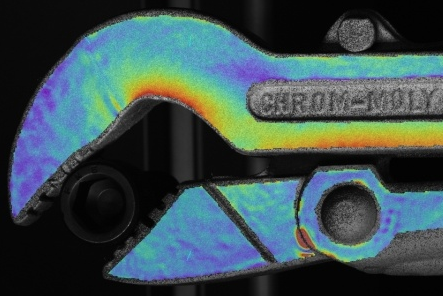

Guidelines for conducting DIC measurements in conjunction with mechanical testing of a planar test piece

This guide is designed to be both a primer training document geared towards new practitioners of DIC (supplementing vendor-based documentation) as well as a reference for experienced users. The Good Practices Guide (GPG) focuses on measurement setup, image correlation, and basic post-processing of DIC data for strain computations.

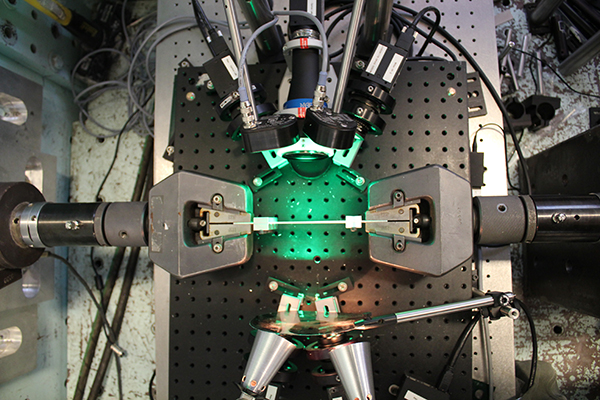

The purpose of the DIC challenge is to supply the image correlation community with a set of images for software testing and verification. This includes both commercial codes and university codes. All the information is freely disseminated at the DIC Challenge website and participation in the challenge is open to all.

Test images have been created both experimentally and synthetically. The DIC Challenge committee members will evaluate the results from each code and report them in a journal paper. Details of the creation of the images will also be recorded in a published paper so participants can understand how the images were created.

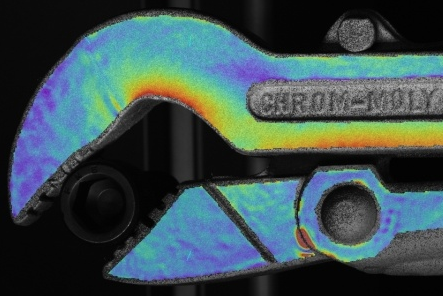

Digital image correlation is a non-contact means of measuring motion and deformation using digital images of the object of interest. It’s used for a wide variety of applications from characterizing material properties to identifying structural damage and quality testing in manufacturing.