Spotlight on Lauren Reid – Pioneering the Future of Aerospace with Digital Image Correlation

Introduction

In the ever-evolving field of aerospace engineering, innovative technologies like Digital Image Correlation (DIC) are revolutionizing how we approach aircraft design and testing. One of the bright minds at the forefront of this transformation is Lauren Reid, a Test Technologist at Airbus. In this blog post, we delve into Lauren’s journey, her experiences with DIC, and her insights on its impact on the aerospace industry.

Lauren Reid: A Profile

Educational and Career Pathway

Lauren’s journey in engineering began at the University of Toronto, where she pursued her degree in Aerospace Engineering. A pivotal career moment occurred during a 12-month internship in Experimental Mechanics she did with Airbus in 2017. It was here that Lauren was first introduced to DIC, working under the guidance of experts like Eszter Szigeti. This experience laid the foundation for her future endeavors in the field. Reid cites this mentorship as invaluable in teaching her “technical work but also the importance of being inquisitive and continuously pushing the boundaries of the industry.”

After rejoining Airbus full-time in 2019 through their Graduate Scheme, Lauren explored various roles, gaining expertise in stress analysis, design, business operations, and experimental mechanics. In 2021, she embarked on her current position in Structures Test- Advanced Metrology, where DIC plays a pivotal role.

Proudest Career Moments

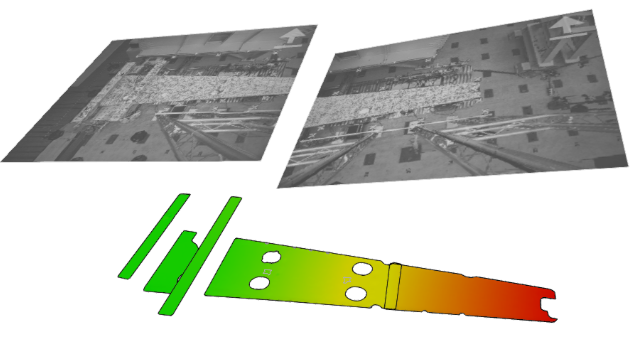

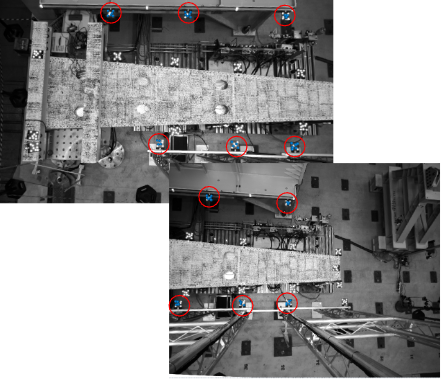

Lauren’s career is marked by continuous growth and the pursuit of new goals. A standout project for her is ‘Smarter Testing,’ aimed at replacing full-scale physical tests with virtual testing to optimize product development timelines. A key part of this project involved speckling a full-scale wing for static testing and validating simulations using DIC results, a testament to her innovative approach in the field.

The Role of DIC in Lauren’s Career

Lauren’s first encounter with DIC was during her internship in 2017. She notes the simplicity and versatility of the technology, which left a lasting impression. “I vividly remember sitting in a warehouse in France speckling a large panel with a sharpie for a bird strike test… The setup was with high speed and gave some great insight,” Lauren recalls. Now, as a Work Package Leader for Advanced Metrology, DIC is an integral part of her work, constantly pushing the boundaries of its application in Airbus’s industrial structures test facility.

Impact of DIC and iDICs in Aerospace

Revolutionizing Aerospace Testing

DIC’s full-field, non-contact nature makes it an invaluable tool in aerospace testing. Lauren explained that in Structures Test at Airbus, it plays a crucial role in design methods development and verification, certification, continued airworthiness, and manufacturing processes. Lauren also noted that they “test all levels of the ‘test pyramid’ from small scale coupons to large scale aircrafts.” She states that this test process is expensive and time consuming, but with “radical rethinking” hybrid testing is being developed to combine physical and virtual methods that utilizes DIC to reduce the time and cost associated with traditional testing methods.

Networking and Growth Opportunities

Lauren states that her participation in the iDICs conference this past year opened doors to global networking and collaboration opportunities, and encourages other individuals and organizations to participate. She believes that such platforms are crucial for knowledge exchange and collective growth in the field.

The Importance of iDICs Certification

Lauren recently attended the DIC 201 course in Japan, gaining deeper insights into complex DIC setups. She advocates for iDICs certification, emphasizing its importance in ensuring a comprehensive understanding of DIC techniques, especially as the industry moves towards using DIC data for certification purposes.

Conclusion

Lauren Reid’s journey and her work with Digital Image Correlation at Airbus highlight the transformative potential of this technology in aerospace engineering. Her story is not just about personal achievements but also the broader implications of DIC in shaping the future of aerospace testing and design. As we look forward to more innovations from Lauren and her team, it’s clear that the sky is not the limit but just the beginning!